Moving and Refurbishing Antique Heavy Machinery

An incomplete overview of my experiences with heavy machinery.

Over the years I have worked closely with my friend Rob Reeve to collect and refurbish heavy machinery. And through this journey I have met fantastic and interesting people, went to interesting places, experienced time-capsules of America's industrial history, and learned so many things. And all of this was only possible through my friends enthusiasm for industrial history and machining. So lets dive in to what this is all about!

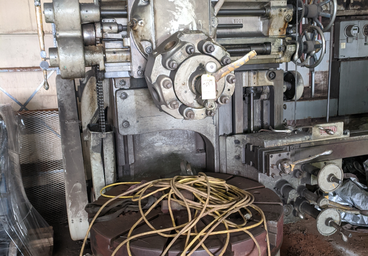

At last count (2018), a total of 41 machines have been acquired ranging from a small drill press and a watch making mill to a 5200lbs Reed-Prentice Lathe and a 6800lbs Fellows No. 6 Gear Shaper. Through the years, while we have both lived in and around Boston, we have moved, disassembed, and refurbished various machines and devices which we have collected. This work has taken place on the hottest days of summer to the coldest days of the New England winter, from New Jersey to the white mountains after a snow storm. The one constant is that we always seem to find insane deals on older machinery through various contacts and craigslist posts.

Though many days and nights have been spent in this endeavor, I have only managed to take pictures of a fraction of it. This is due to us being so focused on not (A) dropping the machine and cracking the cast iron, (B) hurting ourselves, or (C) too tired and greasy to pull out our phones to take pictures, so the pictures I do have are limited in scope and quantity. But I hope you enjoy them as much as we enjoy looking back, bewildered at what we have moved and the quantity of stuff we have moved.

And at this point in our journey, after review, I hope you will agree that both Rob and I can consider ourselves experienced riggers and well versed in heavy machinery. Enjoy!