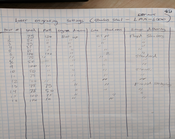

[Late '17 <-> Early '18] Cermark LMM-6000 Power Setting Tests

Description of Project

General Tests done to determine optimal settings for Cermark LMM-6000 with a 120W Epilog CO2 laser.

Processes Applied:

Summary:

From my experiments with Steel, Stainless Steel, and Aluminium I have determined that using a speed of 70-75 and power of 100% on a Epilog 120W CO2 laser will yield the best results in marking your parts. One of the more interesting projects I have done with the cermark laser marking paint is to create an angular ruler for the MIT PSFC-HEDP accelerator chamber. This was achieved by water-jetting the ruler and some holders/alignment features out of sheet stainless steel. Once cut, I used the alignment features to setup the ruler in the laser cutter and proceeded to use the engraving feature of the laser cutter. (Below test piece is stainless-steel)

Then using the optimal settings, I later did tests on size and spacing using the settings within solidworks letter tool. This allowed me to determine the limitations of my chosen 'optimal' settings. (Note this is mild steel)