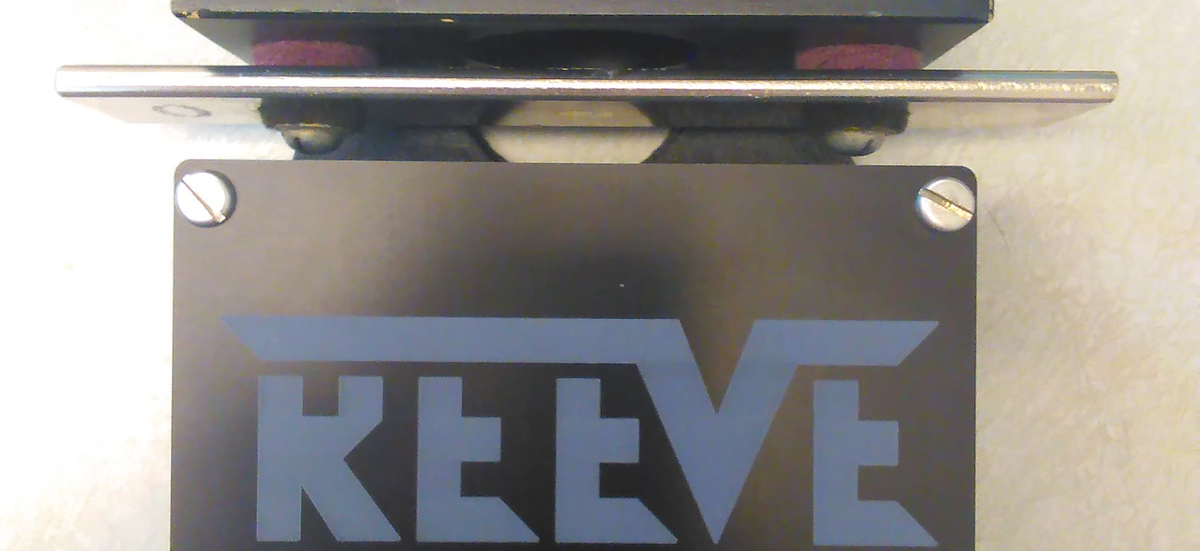

[9.15.16] Reeve Doorbell

Description of Project

A friend is moving into a new space where he setup a few machines, and every shop space needs a door bell. So I decided to refurbish a working xylophone door bell, with a bit of customization.

Processes Applied:

Summary:

This project took more patience than skill in my opinion. Overall the project was a simple progression of process;

Stage one involved perfecting the design and testing it by laser cutting test pieces out of acrylic. The design was a combination of my friend's customized personal logo and the German word for house. As for making sure all the holes aligned properly, I did extensive measurements before the first test print. This stage ultimately took a few test cuts to get out all the kinks.

Stage two involved waterjetting the overall shape out of thin stock anodized aluminum. I initially only cut one test piece and the final piece. The test piece was used in the next step for testing.

Stage Three, this step was focused on first testing various raster settings on the laser cutter on the test piece. This allowed me to create a reference for both this project and future laser engraving projects that are designed around the use of thin stock anodized aluminum. Once I had chosen the settings, all that was left was making sure the alignment was good and waiting patiently for the slow etching process to finish.