[06.2020]$40 for Precision: A Bandsaw of class

Description of Project

In the earlier part of the pandemic I was able to find a pneumatic surface grinder and bandsaw at an industrial auction (Online) in waltham, MA. What I didn't realize at the time of purchase was just how good a bandsaw could be... let alone a $40 one.

Processes Applied:

Summary:

This project started with the purchase of a bandsaw for $40 in an industrial auction. The goal of this purchase was to provide a basic platform for Rob and myself to build an automated bandsaw. But what we found redefined what we thought what a good bandsaw could be.

The Bandsaw; W.F. Wells Model L-9. From the outset we started to notice the quality of engineering that went into the design of this bandsaw. The first was the design of the drive, the bandsaw used a helical internal gear mated to the motor with a simple external helical gear. This design decision drastically reduces any drive noise due to the constant engagement one gets in the involute curve of the helical tooth.

Once we transported the bandsaw from the auction, we immediately went about lubricating the machine to prime it for some test cuts. That is when we found the next bit of clever mechanical engineering; The blade guides. Bandsaw blade guides tend to have simple set screw to assist in aligning the two guides. But when we brushed off all the old chips and grease, we were left with a beautifully designed worm gear alignment feature on each blade guide. Simply put, the use of a worm gear allows for precise incremental adjustments to be made to the blade guides; enabling you to get the blade precisely perpendicular to your stock.

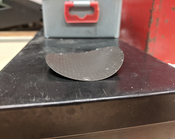

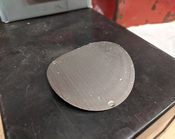

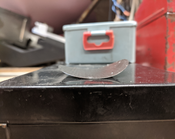

Testing the bandsaw; So to put the bandsaw through its paces we took some cuts of aluminum and steel stock. Stepping through various feed rates and cut thicknesses. The bandsaw was performing better than we expected, but nothing prepared us for when we pushed the limits of what we thought a bandsaw could do... We attempting cutting thinner and thinner sections off of a 2" diameter stainless steel round stock. Ultimately producing a Pringle of a chip; ~0.012" +/- 0.001" across the entire piece... my friend Rob was practically raised in a machine shop, and he was awestruck, I some how managed to acquire us the most precise bandsaw he had ever seen... for $40!

The truly shocking thing we noticed after falling in love with this bandsaw, is the fact that MITERS dinky bandsaw is an smaller and older model of our bandsaw... with a previous generation of the worm driven guides. So I look forward to cleaning and tuning the MITERS bandsaw up post-covid, because who knew we had a diamond sitting unpolished right in the middle of the shop!

We went on to start modifying it to enable automated feeding of stock; This part of the project is still ongoing.